|

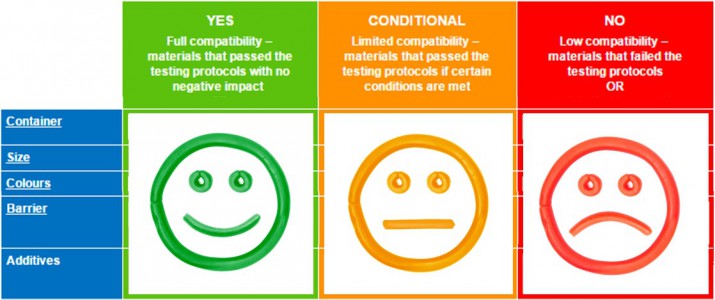

Full compatibility –

materials that passed the testing protocols with no negative impact

OR

materials that have not been tested (yet), but are known to be acceptable in PET recycling

|

Limited compatibility –

materials that passed the testing protocols if certain conditions are met

OR

materials that have not been tested (yet), but pose a low risk of interfering with PET recycling

|

Low compatibility –

materials that failed the testing protocols

OR

materials that have not been tested (yet), but pose a high risk of interfering with PET recycling

|

|

Material

|

|

|

|

|

Size

|

|

|

|

|

Colours

|

|

|

Metallic

|

|

Barrier for monolayer

|

None; PET based oxygen Barriers or Scavenger with no yellowness effects after TCEP oven test.

|

PET based oxygen Barriers or Scavenger with limited yellowness effects after TCEP oven test

|

EVOH; PA; any other barrier; any other oxygen scavenger

|

|

Barrier for multilayer

|

|

|

Barrier material laminated or incorporated to the main PET layer. PVCD and other halogenated compounds as barrier

|

|

Additives

|

Silicone surface coating (on coating area); Antilocking masterbatch; None of them should affect clarity

|

Any other additive (UV stabilisers; AA blockers; optical brighteners; antilocking; anti-stat agents; anti-fogging (on coating area)) With Limited effect on clarity to be measured

|

Bio/Oxo/Photodegradable additives; Nanocomposites, any BPA containing material

|

|

UNPRINTED Lidding films - Closure systems (with glue not harming the recycling process)

|

PET; OR Floating combination of plastics with density < 0,95 g/cm3 ; NO glue residuals; If no PET, no lidding film residual on the tray. SiOx, AluOx plasma for barrier.

|

|

any other sinking film with density > 1 g/cm3 (to be proven with sink/float test)

|

|

PRINTED Lidding films - Closure systems (with glue not harming the recycling process)

|

NO PRINITNG PREFERED. OR plastics/combination of floating plastics with density < 0,95 g/cm3; NO glue residuals; foamed PET based films where foamed structure is not getting destroyed @ 90°C ; If no PET, no lidding film residual on the tray. SiOx and AluOx plasma for barrier

|

|

any other film, any BPA containing material

|

|

Labels (with adhesive not harming the recycling process - see labels adhesive section)

|

NO LABEL PREFERED. Plastic labels where label has a density < 1 g/cm3 in the more heavily printed and adhesive area

|

BPA-Free Paper labels not loosing fibbers (pulping) and floating

|

Plastic labels where label has a density > 1 g/cm3 in the more heavily printed and adhesive area - Paper labels loosing fibbers (pulping) - Paper containing BPA - non floating paper labels, any BPA containing material

|

|

Adhesives for: 1.Sealing layer, 2.Labels/other components, 3.Lamination

|

Adhesives with 100% removing ratio and no adhesive residuals on flakes @ 70°C testing temperature

Water or alkali soluble in 60-80°C.

Peelable films not leaving not leaving residuals on the flakes

|

adhesives with 100% removing ratio and no adhesive residuals on flakes @ 85°C testing temperature

|

Bi-component solventless adhesives, any BPA containing material

|

|

Inks

|

|

|

|

|

Direct Printing

|

|

|

Any other direct printing,any BPA containing material

|

|

Other Components

|

NO other components are preferred

|

Inserts in HDPE / LDPE / PP, Soaker pads, bubble pads and paper & carboard - all inserts should be completely removable and leave no traces

|

PVC and other halogenated compounds / PS / EPS / PU / PA (Nylon); PC / PMMA Thermoset plastics / metals; non compliant soaker pads

|

|

Liners for multilayer packaging, seals and valves

|

|

|

Materials with density >1gr/cm3 (eg. PVC and other halogenated compounds, silicon, metals, silicone (even with density <1g/cm3). Foamed PET. Any other floatable or non floatable materials made of wood or cellulosic materials |

|

Sleeves and wraps

|

Sleeves with partial coverage and wraps with full coverage of the package in PO, PE, PP, OPP. All with density <1g/cm3

|

Full sleeves or wraps in PO,PE,PP, OPP all with density <1g/cm3. PET based sleeve with density <1g/cm3

|

Materials with density >1g/cm3 (eg metal, PVC and other halogenated compounds, PS, PETG)metallized materials. Foamed PETG (even with density <1g/cm3)

|

|

Tamper evidence wrap

|

PE, PP,OPP all with density <1g/cm3

|

|

Materials with density >1g/cm3 (eg metal, PVC and other halogenated compounds , PS, PETG)metallized materials. Foamed PETG (even with density <1g/cm3)

|

|

Colours for coloured PET thermoforms

|

Light and opaque NIR detectable colours

|

|

Fluorescent colours, metallic, non detectable colours

|

|

Direct Printing for coloured PET thermoforms

|

|

Any other direct printing on the main component of the packaging

|

|

Member Login

Member Login

News

News

_1435074824_1710241703.jpg)

_1713772351.png)